Separating floor insulation

Separating floors are designed to minimise sound transmission between floors in flats, hotels, offices and other multi-occupancy and/or multi-storey buildings. They are also used in commercial or public buildings in order to maintain energy efficiency where exposed floors are situated directly above or below car parks or access ways.

Another key requirement of a separating floor is enhanced levels of fire performance as specified in Approved Document B of the Building Regulations.

Separating floor are generally either timber or concrete construction, and there are effective mineral wool insulation solutions for both.

Timber frame

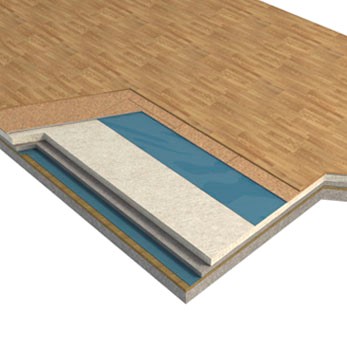

Timber frame separating floors are typically constructed using either engineered I beams, solid timber joists or metal web joists. In each case, the installation of mineral wool insulation in the void between the beams will absorb sound, improve acoustic performance and also deliver significant benefits in terms of thermal performance. Mineral wool insulation can also be installed as a resilient layer between the structural deck and the floor surface itself, substantially reducing impact sound.

Timber floor upgrade

An existing internal timber floor can be upgraded to a separating floor in a number of ways, including through the installation of a new independent ceiling below or a new platform floor above. Either way, mineral wool insulation will provide improved acoustic and thermal performance.

Concrete

Concrete separating floors can be constructed using a range of different methods including in-situ casting, concrete planks and permanent formwork. They can also incorporate screed layers and under floor heating. Whatever the construction method, acoustic and thermal performance will be enhanced with the installation of mineral wool insulation either above or below the floor.

The benefits of Mineral Wool

- Value for money - more cost effective than any other material available

- Thermal performance - compression fit minimizes gaps at joints

- Acoustic performance - excellent sound absorption helps compliance with Part E

- Environmental - uses recycled material, zero ODP & GWP, BRE Green Guide A+ to B

- Fire properties - non-combustible and A1/A2 Euroclass fire rated helps compliance with Part B

- Easy-to-fit - simple installation process